Selecting a durable hose that can withstand oil is essential. In line filters, one problem with oil is that you end up hiding how much contamination there really is, and in a very short period of time all those fine bits of dust or abrasive parts are grinding around on expensive control valves such as the joy stick controls for huge diggers. Therefore, the use of Demai heat resistant oil hose is preferred. These hoses are specially manufactured to combat oil and other viscous liquids, thus making their durability last longer than expected and performance better.

Demai wear resistant hoses are manufactured using special materials that can withstand the harsh conditions created by oil. The most common among these layers being Steel wire or Polyester fabric, improving longevity and strength in hoses. This means, they can handle the rough conditions that it might face while in use. They are also built to withstand a bit of wear and tear, designed not to kink, crack or fail with frequent use. Oil-resistant hoses can help you ensure that your equipment will keep running effectively.

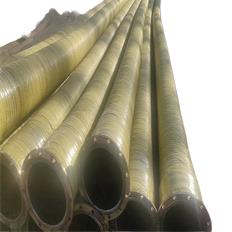

For instance, if you are moving heavy liquids like oil or other viscous fluids, then a more substantial weight as well as an oil-resistant hose is what your needs. Demai heat transfer oil hose is made to endure the high pressure that comes with any industrial based job. These doors are composed of many layers containing tough materials which makes them more sturdy and strong. A short hose like this can last many years, and some of these hoses incorporated steel wire or other strong materials inside them so that they will not kink easily nor get pinched as quickly (even when under pressure). That makes certain they can do the job without having failure.

The best option for getting high performance with your hoses is to use Demai oil hose. Durable hoses made for the people who need them to perform at a high level. They utilise the best materials to enable harsh operating conditions and withstand industrial usage. These hoses will typically have multiple layers of tough materials, such as Aramid fiber or other high-tech extensions that improve their strength and resistance to damage. This makes them last longer working very well in severely conditions as being until a fast charge level.

Selecting an oil-resistant hose will improve the performance and life of your machines. For Durable Hose: Wear and tear sand leaks could easily be reduced with oil-resistant hoses that keeps you out of garage to save on repairs. Therefore, when handling oil or other fluids in your work: with the proper type of hoses that suits all these requirements. This will help your work to run smoothly and efficiently, freeing you up to write about what actually matters. Choose the best, choose Demai's Oil resistant hose

Oil resistant hose has an experienced R D center, R D team is robust. We're determined to break the old rules, continually improving and continually surpassing. Special-purpose rubber hoses can be tailored to meet customer demands.

Demai Rubber and Plastics can offer technical assistance to professionals and Oil resistant hose. we adhere to a strict quality control system to ensure each product's performs well and is of high quality. Also, we provide timely delivery, prompt responses, products with ISO9000 certification, high quality, high reliability.

Rubber raw materials from the top suppliers in the world, of Oil resistant hose, following rigorous testing to make sure there are no contaminants and pollution-free. The firm has its own distinctive mixture of rubber to guarantee the durability and dependability of the product, high-end production techniques, low cost, low cost.

Our after-sales services are prompt. We'll resolve any issue that occurs during the warranty timeframe within Oil resistant hose. We provide excellent service with the assurance of the quality of the product.

Copyright © Demai Rubber & Plastics (Hebei) Co., Ltd. All Rights Reserved - Privacy Policy