Ever wondered how factories and industries can manage to move extremely hazardous liquids like acids from one location to other without those long ACID HOSES even breaking, let alone having anyone hurt. Now you might think that's difficult to achieve… You need a hose like this: PTFE lined hosing!

PTFE is short for polytetrafluoroethylene, which is an engineered material made to easily stand up against harsh chemicals and high temperatures. PTFE lined hose creates a more durable chemically resistant structure when used as the lining of inside hoses which can be utilized in extremely hazardous conditions. And because of this, workers can freely do their job without having to worry about leaks or accidents.

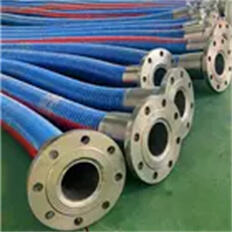

Some of the liquids and gases are highly dangerous in nature which requires strong hose pipe such that they can able to manage a proper way without causing any problems. These are some of the many reasons why Fluoropolymer lined hoses like PTFE-lined hose work so well and remain a popular product option in these specific industries. This flexibility allows the hoses to be bent and twisted without cracking making it very useful for busy factories.

Perhaps the key characteristic of PTFE lined hoses is that they are able to withstand high heat without breaking down. Such material are ideal for working with hot liquid or gas in chemical industries. In a factory, you may be transporting very high-temp liquids… PTFE hoses will have no issue moving that liquid without being at risk of breaking or leaking. Some hoses of other constructions can become fragile at such temperatures, or even melt but PTFE types are still holding strong and reliable.

After several years of use, stiff chemicals can damage normal hose pipes and create leakages that might bring about accidents. While, PTFE lined hoses are corrosion-resistant. This makes them very rust and degrade-resistant, which is a great quality when it comes to transporting hazardous liquids or gases. By using PTFE hoses, factories lower the risks of leaving liquid components leak out and keep all processes running smoothly.

Hoses are subjected to some of the worst conditions in factories where strong chemicals and other materials are processed. The best hoses for these jobs are generally PTFE lined, as these will last many years and resist damage from the chemicals they carry. Moreover, these hoses can be tailored to meet the unique requirements of other factory applications, which do it even more versatile. In conclusion, a PTFE lined hose can be used for virtually any type of liquid or gas that may pass through a factory.

Our after-sales services are prompt. We'll resolve any issue that occurs during the warranty timeframe within ptfe lined hose. We provide excellent service with the assurance of the quality of the product.

Demai Rubber is a professional R D ptfe lined hose, R D team is well-established. We're dedicated to breaking traditions, continually innovating and continually beating. Customized to meet customer requirements. special-purpose, high-quality rubber hose products.

Rubber raw materials from top suppliers in the world, of excellent quality, following ptfe lined hose to ensure there are no contaminants and pollution-free. The business is the only one with its own mix of rubber to ensure the longevity and reliability of products, advanced production technology and low cost prices.

Demai Rubber and Plastics provides skilled technical support and sample confirmation. We have strict quality control procedures to ensure that every product's performance is stable and excellent. We also provide ptfe lined hose, quick responses, products with ISO9000 certification, high quality, high consistency.

Copyright © Demai Rubber & Plastics (Hebei) Co., Ltd. All Rights Reserved - Privacy Policy